REPAIRS

One of our main customers is Navantia Repairs, specialised in repairs and conversion of vessels.

One of the most significant works, due to the precision required and perfect coordination, is Tank Coating. The experience of the company over the last 30 years is our guarantee.

TANK COATINGS

Currently, the International Maritime Organization requirements demands very specific works in the tanks of the vessels, and any mistake can be a disaster. Gaditana de Chorro y Limpieza, S.L. has its own specialised teams in this kind of jobs, so we can offer the best quality and quick realization of the works in order to accomplish with the schedules.

OFFSHORE AND PROTECTIVE COATINGS

Since 1998, we have new construction projects in the Dragados Off-Shore Yard in Puerto Real (Cádiz).

Within our personnel, we have a wide number of certified FROSIO (NS476) and NACE Inspectors.

In 2005, we were awarded by Nexen Petroleum UK Ltd. for our exceptional job on surface preparation and coatings application in the Buzzard Process Deck.

SURFACE PREPARATION

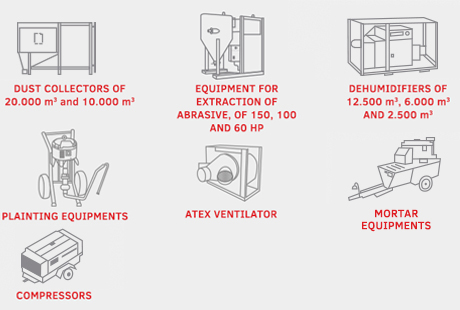

One of our main activities is the surface preparation of the steel, we are highly specialised and we have equipments and human resources enough and certified to comply with the following standards:

NACE: NATIONAL ASSOCIATION CORROSION ENGINIEERS (NORMA AMERICANA)

BS 4232: BRITISH STANDARDS INSTITUION (NORMA BRITÁNICA)

SIS 055900: SWEDISH STANDARDS INSTITUION (NORMA SUECA)

SSPC: STEEL STRUCTURES PAINTING COUNCIL (NORMA AMERICANA)

SPECIALISED IN:

Dry Abrasive Blasting /

Wet Blasting /

Sponge Jet Blasting /

Blasting with Blastrac authomatic equipments for surface preparation on decks /

Surface preparation by Mechanical means /

We have personnel with SSPC C7 “Certified abrasive blaster” homologation.

High and Ultra High Pressure Washing:

By using high and ultra high pressure washing for surface preparation, we can achieve optimal results for the subsequent coatings application.

We have last generation equipments, with a wide range of water and pressure flowrates, and we support safety and professionality so the jobs are carried out according to our customer’s necessities.

MAIN APPLICATIONS:

/ Hulls, tanks, decks, superstructures in vessels.

/ Fuel storage tanks.

/ Pipes for gas, oil and petroleum derivatives.

/ Off-shore platforms.

/ Bridges piles.

We have personnel with SSPC C13 “Certified water jetting” homologation.

NEW CONSTRUCTIONS

Gaditana de Chorro y Limpieza has been involved in numerous projects, among others, new constructions in the shipyards in Puerto Real (Cádiz), CNN, La Naval (Sestao), Murueta, etc.

The most relevant activities are:

/ Surface preparation.

/ Application of anticorrosive systems.

/ Installation of scaffolds.

Within our personnel, we have available many FROSIO Level III Inspectors, as per NS476 standard, in order to accomplish with the coating systems in ballast tanks and double hulls of vessels as per IMO MSC 212 (82).

APPLICATION OF ANTICORROSIVE SYSTEMS

Currently, we are a reference company in the naval and offshore sectors with a wide experience in anticorrosive coatings, pointing out:

/ Application of anticorrosive systems according to norwegian standard Norsok M-501.

/ Application of anticorrosive systems according to ISO 12944 standard.

/ Application of anticorrosive systems according to International standards.

The company has its own technical department dedicated to study and supply technical advise when choosing the adequate anticorrosive systems for each case, so longer lifetimes can be guaranteed.

We have SSPC C12 “Certified spray applicator” homologation.

METALIZATION

One of our most specialized activities is the application of thermal spray coatings, such as thermal spray aluminium (TSA), zinc (TSZ) and its alloys. It can be applied to:

/ Underdeck.

/ Flares.

/ Carbon Steel, dúplex and superduplex pipes.

/ Splitter columns.

/ Vessels.

/ Conduits for acid…

PASSIVE FIRE PROTECTION (PFP)

In 2009, Gaditana de Chorro y Limpieza S.L. started its homologation process with PPG Coatings and Akzonobel for fireproofing application. Nowadays, we are certified as an applicator company with different manufacturers:

/ Pittchar applicator certificate (PPG Coatings)

/ Chartek applicator certificate (Akzo Nobel)

/ Jotachar applicator certificate (Jotun)

/ Pyrocrete applicator certificate (Carboline)

We have an engineering department dedicated to study every project and supply technical advise to our clients on the selection of Passive Fire Protection systems, for hydrocarbon and cellulosic fires.

Our objectives are Onshore and Offshore projects:

Offshore market:

/ New construction oil platforms.

/ Maintenance in oil platforms.

Onshore Market:

/ Refineries.

/ Gas plants.

Español

Español